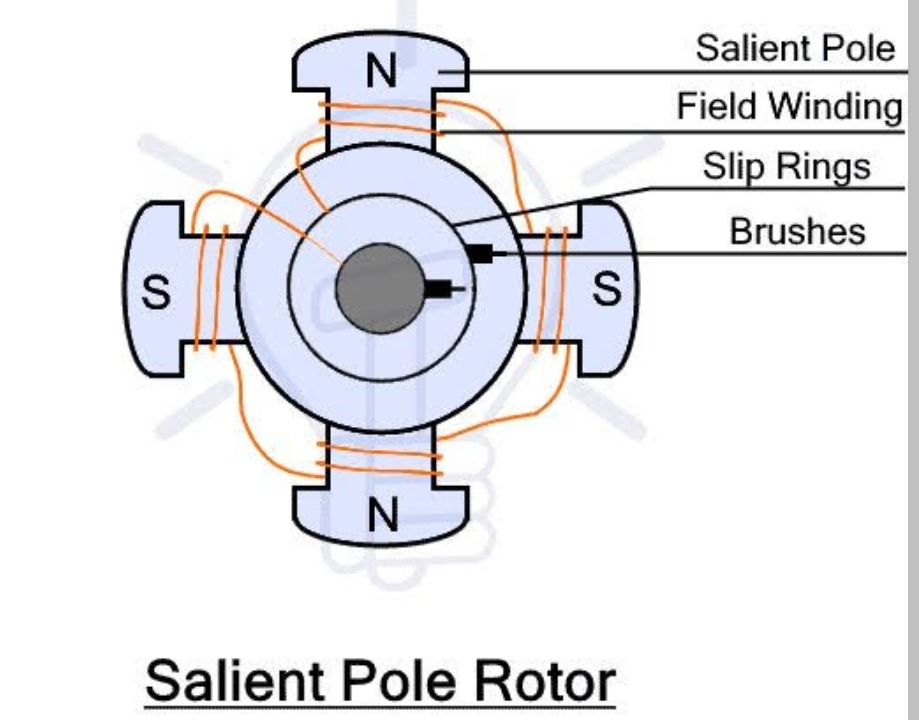

Salient Pole:

A salient pole is a type of magnetic pole used in electrical machines, particularly in synchronous motors and generators.

Applications:

- Synchronous Motors: Salient poles improve starting torque, efficiency, and power factor.

- Hydroelectric Generators: Salient poles reduce eddy current losses and increase efficiency.

- Wind Turbines: Salient poles optimize energy production and reduce maintenance.

- Electric Vehicles: Salient poles enhance motor performance, efficiency, and reliability.

- Power Systems: Salient poles stabilize grid frequency and voltage.

Advantages:

- High power density

- Improved efficiency

- Enhanced reliability

- Reduced maintenance

- Increased starting torque

Disadvantages:

- Complex design

- Higher cost

- Limited speed range

- Increased vibration

- Noise generation

Salient Pole Machines:

- Permanent Magnet Synchronous Machines (PMSM)

- Electrically Excited Synchronous Machines (EESM)

- Hybrid Synchronous Machines (HSM)

Design Considerations:

- Pole shape and size

- Magnet material selection

- Winding configuration

- Cooling systems

- Mechanical stress analysis

Would you like:

- Detailed design guidelines

- Performance analysis

- Comparison with other magnetic pole types

- Application-specific solutions

- Research papers and case studies

Please respond!

Detailed Design Guidelines:

- Pole arc: 30-60 degrees

- Pole shoe shape: Rectangular or trapezoidal

- Magnet material: Neodymium (NdFeB), Samarium-Cobalt (SmCo)

- Winding configuration: Star or delta

- Cooling system: Air-cooled or liquid-cooled

Performance Analysis:

- Efficiency: 90-95%

- Power factor: 0.8-1.0

- Starting torque: 1.5-3 times rated torque

- Speed range: 100-3600 rpm

- Temperature rise: 80-120°C

Comparison with Other Magnetic Pole Types:

- Smooth poles: Lower efficiency, simpler design

- Inset poles: Higher efficiency, more complex design

- Buried poles: Higher reliability, lower starting torque

Application-Specific Solutions:

- Wind turbines: Direct-drive, high-torque salient pole motors

- Electric vehicles: High-efficiency, high-power salient pole motors

- Hydroelectric generators: Large-scale, high-efficiency salient pole generators

Research Papers and Case Studies:

- “Design and Analysis of Salient Pole Synchronous Motor” (IEEE)

- “Salient Pole Synchronous Generator for Wind Turbine Applications” (Elsevier)

- “Optimization of Salient Pole Motor Design for Electric Vehicle” (SAE)

Different features of Salient Pole machines:

Electrical Features:

- High power density

- High efficiency (90-95%)

- High power factor (0.8-1.0)

- Low stator current

- High starting torque

Mechanical Features:

- Robust construction

- Low vibration

- High reliability

- Compact design

- Easy maintenance

Magnetic Features:

- High magnetic flux density

- Low magnetic leakage

- High saliency ratio

- Optimized pole shoe design

- Reduced eddy current losses

Control Features:

- Vector control

- Direct torque control

- Field-oriented control

- Sensorless control

- Closed-loop control

Thermal Features:

- Air-cooled or liquid-cooled

- High thermal conductivity materials

- Optimized heat transfer design

- Reduced temperature rise

- Increased lifespan

Materials:

- Permanent magnets (NdFeB, SmCo)

- Electrical steel (Si-steel, Ni-Fe)

- Copper or aluminum windings

- Insulation materials (epoxy, polyester)

- Bearing materials (steel, ceramic)

Design Tools:

- Finite Element Method (FEM)

- Computational Fluid Dynamics (CFD)

- Electrical circuit simulators (SPICE)

- Mechanical CAD software (SolidWorks)

- Optimization algorithms (genetic, particle swarm)

Applications:

- Wind turbines

- Electric vehicles

- Hydroelectric generators

- Industrial automation

- Aerospace and defense

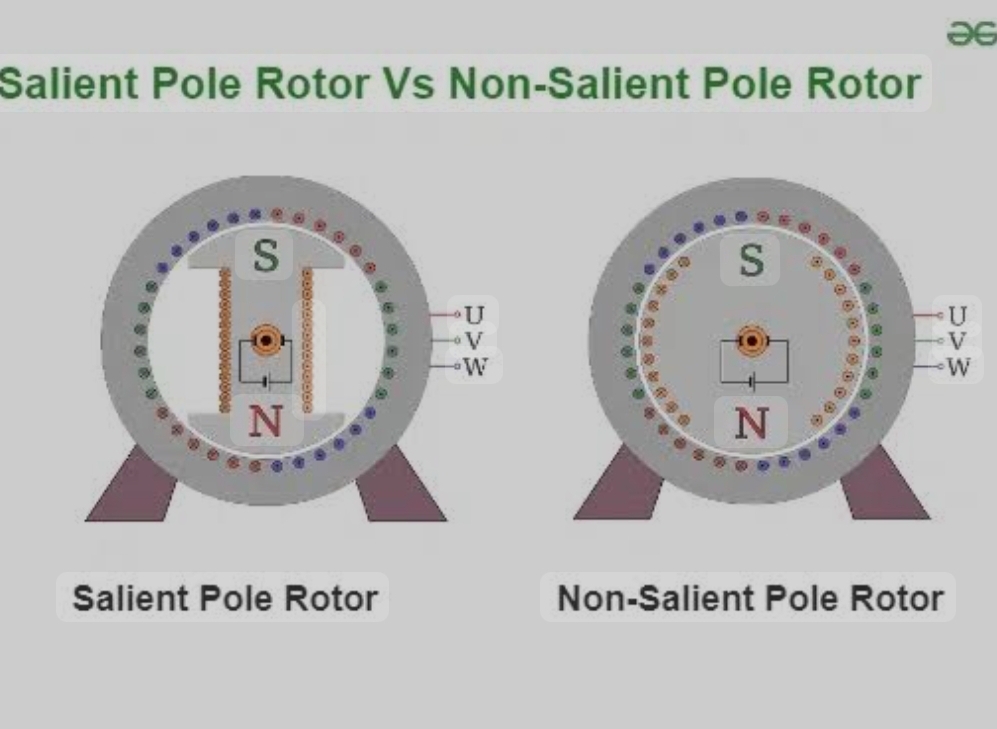

Salient Pole (SP) vs Non-Salient Pole (NSP) machines

:

Salient Pole (SP) Machines:

Characteristics:

- Projection of poles from rotor surface

- Permanent magnets or electrical excitation

- High starting torque

- High efficiency

- High power density

Advantages:

- High power factor

- Low stator current

- High reliability

- Compact design

- Easy maintenance

Disadvantages:

- Complex design

- Higher cost

- Limited speed range

- Increased vibration

- Noise generation

Non-Salient Pole (NSP) Machines:

Characteristics:

- Smooth rotor surface

- No projections or permanent magnets

- Lower starting torque

- Lower efficiency

- Lower power density

Advantages:

- Simple design

- Lower cost

- Wide speed range

- Reduced vibration

- Quiet operation

Disadvantages:

- Lower power factor

- Higher stator current

- Lower reliability

- Larger size

- More complex control

Comparison:

| Feature | Salient Pole (SP) | Non-Salient Pole (NSP) |

|---|---|---|

| Starting Torque | High | Low |

| Efficiency | High | Low |

| Power Density | High | Low |

| Cost | High | Low |

| Complexity | High | Low |

| Speed Range | Limited | Wide |

| Vibration | High | Low |

| Noise | High | Low |

Applications:

Salient Pole:

- Wind turbines

- Electric vehicles

- Hydroelectric generators

- Industrial automation

Non-Salient Pole:

- Fans and blowers

- Pumps

- Conveyors

- General-purpose induction motors